Respirable Crystalline Silica, and the plentiful industries which are associated with it, are under the spotlight after an increase in media attention of late. There has been an increase in reported cases of Silicosis, a deadly disease linked to this substance, in Australian workers (1). All the more shocking is the young age at which some have succumbed. What is RCS and how is it linked to harm in those who work with it? Read on now, and in the next instalment, we’ll discuss what can be done to identify and mitigate these risks to your workers. A case study will help demonstrate this and show how MiSAFE can help.

What is Respirable Crystalline Silica?

The term silica refers to all forms of silicon dioxide. Also known as quartz or crystallized silicon dioxide, both crystalline/free silica and non-crystalline/amorphous silica are encompassed under this term. However, it is the dust particles of crystalline or free silica only which are of greatest concern to health authorities as they deal with what has already been predicted to be the new asbestos of this generation by news media and industry sources alike (2). The dust particles small enough to be inhaled have an industry name: Respirable Crystalline Silica (RCS). They also have a deadly effect.

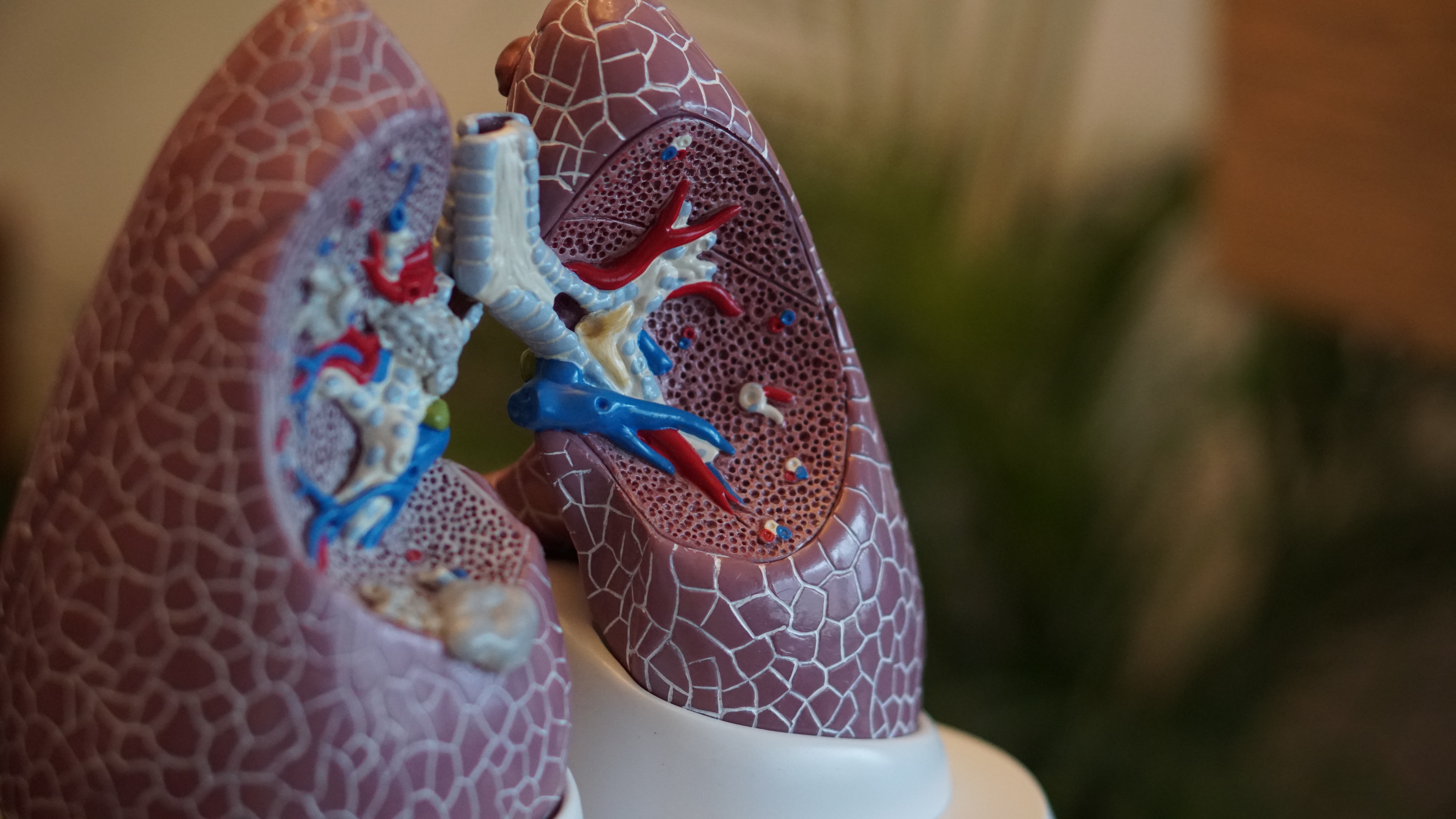

Silicosis

Silicosis is the incurable lung disease caused by the effects of RCS dust. A 2018 audit by the Queensland government of the manufactured stone industry revealed 15 terminal cases out of 98 confirmed silicosis diagnoses (3). These cases are alarming the worker-related industries and clinicians alike because of the young age at which some workers have been diagnosed with the disease. Unlike the last known epidemic of work-related diseases in Australia caused by asbestos, one-off instances of heavy exposure to RCS have the potential to cause fatal harm, as well as the cumulative effect of slow, consistent exposure over many years. There are currently three recognised types of silicosis, characterised by their type of exposure and length of time to develop and cause death: ‘acute’, ‘accelerated’ and ‘chronic’. Acute silicosis begins extremely suddenly after heavy intense exposure. The exposure needn’t be frequent or consistent for the lungs to begin to be affected and serious physical degradation can occur within weeks to a year of exposure (4). Accelerated silicosis develops within 10 years of first use and occurs after high exposure to RCS begins a rapid scarring of the lungs (5). It is the increase in acute and accelerated cases of silicosis, due to the heavy exposure experienced in the manufactured stone industry, that have led to the devastating reports of workers as young as 22 falling victim (6). Chronic silicosis is also a real risk to those in the related industries, as the slow and consistent exposure to RCS – even at low levels – works its devastating effects on the lungs also. Even though the lungs may be affected somewhat differently, or more or less swiftly, in each of these types of silicosis, the destructive result is always the same: the disease is incurable and is a life sentence for its sufferers, unless a complete lung transplant is possible.

Other Illnesses are linked to RCS

If lung disease weren’t enough, it must be noted that RCS has also been linked to renal (kidney) disease, an increased susceptibility to tuberculosis, auto-immune diseases such as scleroderma, rheumatoid arthritis and lupus. Not surprisingly, RCS is an identified Group 1 carcinogenic and can also lead to lung cancer, as well as Chronic Obstructive Pulmonary Disease (7).

Who’s at risk?

One of the inescapable issues surrounding RCS is its prevalence. Since quartz or silica are naturally occurring, we find it almost everywhere from beaches to quarries in the sand, clay or stone all around us. It follows then that the respirable crystalline silica dust unsettled by working in some of these locations or with these materials is also associated with almost every industry that works with the earth. Because of the multitude of materials that are also manufactured using silica, many more industries and sub-industries are also impacted. Here are the most obvious examples: – Earthworks; including but not limited to drilling, cutting and tunnelling – Mining – Building and construction; including but not limited to landscaping, concreting, bricklaying – Manufacturing: especially stonemasonry. Engineered stone benchtops contain a particularly high (between 90 and 97%) content of crystalline silica, exposing workers in this sector even more so than others. This is the sector currently identified as being the most at risk and interventions such as the banning of all dry processing have begun to be enforced (8).

Sources:

(1) Qld media have been reporting on new cases since mid-2018: https://www.abc.net.au/news/2018-09-18/silicosis-warning-kitchen-bench-trade-workers/10262958. Gold Coast stonemason, Anthony White, spoke publicly and to the media about the dangers of Silicosis and his death from the disease was widely publicised by local and international news media in March 2019: https://www.abc.net.au/news/2019-03-13/silicosis-victim-dies-from-disease/10895774, https://www.9news.com.au/national/silicosis-news-australia-gold-coast-stonemason-anthony-white-dies/0c4d8038-1be7-4eea-9b56-5ae0db8bbd9c, https://www.news.com.au/finance/business/other-industries/silicosis-claims-life-of-young-gold-coast-stonemason/news-story/b2d86d96b3a3c29695591fd477c1b51c (2) The ABC references Brisbane lung physician Dr Graeme Edwards: https://www.abc.net.au/news/2019-02-21/silicosis-death-dust-audit-reveals-major-epidemic-worse-asbestos/10830452 (3) According to figures obtained by the ABC, 21 February 2019: https://www.abc.net.au/news/2019-02-21/silicosis-death-dust-audit-reveals-major-epidemic-worse-asbestos/10830452 (4) https://foundation.chestnet.org/patient-education-resources/silicosis/ (5) https://foundation.chestnet.org/patient-education-resources/silicosis (6) In May 2019, it was reported 22 year old Connor Dawes, from the Gold Coast, was the youngest known Queenslander to be diagnosed with Silicosis. https://www.abc.net.au/news/2019-05-30/stonemason-silicosis-class-action-slater-and-gordon/11162554 (7) https://www.safeworkaustralia.gov.au/silica, https://www.cancer.org.au/preventing-cancer/workplace-cancer/silica-dust.html (8) newsGP, 12 October 2018: https://www1.racgp.org.au/newsgp/clinical/ban-dry-processing-to-halt-spread-of-accelerated-s

Images:

Stock Photos by Dave Webb, Robina Weermeijer, Shane McLendon, Alireza Naseri on Unsplash

Recent Comments